Kverneland Satio

Siembra | Sembradoras neumáticas independientes o autónomas

Siembra eficaz y rentable - con flexibilidad preparada para el futuro

Sembradora compacta, independiente, sin preparador ni grada rotativa, para tractores pequeños y medianos

Destacado

- Diseño compacto y ligero - bajo consumo de combustible

- Flexible: siembra independiente de la preparación del lecho de siembra

- Colocación precisa de las semillas

- Rentable

- Alta velocidad de siembra - gran rendimiento

Descripción

La Kverneland Satio es una sembradora independiente y compacta. Es la máquina ideal para explotaciones pequeñas y medianas. Como sembradora suspendida en tractor sin equipo de preparación del lecho de siembra. La Kverneland Satio combina un diseño compacto y ligero con la demostrada calidad Kverneland. El centro de gravedad cercano garantiza un requisito de potencia mínimo de 75cv y permite velocidades de trabajo más altas. En funcionamiento en solitario, la Kverneland Satio ofrece una flexibilidad extra para adaptarse también a condiciones meteorológicas extremas.

La sembradora rígida Kverneland Satio está disponible en anchos de trabajo de 3,0 y 4,0 metros. Las ruedas de la Kverneland Satio pueden ajustarse fácilmente a cualquier ancho de vía. Esto garantiza un contacto constante con el suelo que acciona el dosificador tradicional con cadena de la Kverneland Satio. Los borra-huellas integrados son estándar. Los discos CX-II con o sin ruedas de consolidación se sujetan a la barra de siembra mediante bridas y permiten elegir la distancia entre hileras correcta de 12,5 cm o 25,0 cm para adaptarse a los distintos sistemas de cultivo. La presión de las rejas se ajusta mecánicamente.

La sembradora independiente neumática Kverneland Satio tiene una capacidad de tolva de 750 litros, 1.000 litros con extensión. Para el control electrónico, es necesario configurar la máquina con las variantes FGS y Signus aunque el dosificador no cambie a ELDOS sino que prosiga siendo el dosificador clásico Accord.

¿Cuáles son las ventajas de una sembradora Independiente?

La sembradora en solitario o independientes Kverneland Satio están diseñada para los agricultores modernos que desean una siembra precisa, eficiente y sostenible, sin depender de la preparación del lecho de siembra. Esta operación en solitario ofrece la máxima flexibilidad y mayor control sobre el momento, la profundidad de siembra y las condiciones del suelo, lo que se traduce en mayores rendimientos y menores costes de insumos. La siembra en solitario amplía su ventana operativa y ayuda a equilibrar los picos estacionales de carga de trabajo, ya que no está atado a otros calendarios de trabajo en el campo. Kverneland Satio permite velocidades de trabajo más rápidas y una colocación precisa de las semillas incluso a poca profundidad. Esto significa más hectáreas en menos tiempo sin comprometer la precisión.

Reducción de la compactación del suelo y de los costes de combustible

La siembra en solitario requiere menos potencia del tractor, minimiza la compactación del suelo y reduce el consumo de combustible.

Mejor control de malas hierbas y plagas

Con el avanzado disco CX-II, Kverneland Satio garantiza una colocación precisa de las semillas con una alteración mínima del suelo. Esto mejora el control mecánico de las malas hierbas y favorece las estrategias de gestión integrada de plagas.

Destacado

- Diseño compacto y ligero - Bajo consumo eléctrico.

- Más flexible - siembra independiente de la preparación del lecho de siembra.

- Colocación precisa de las semillas - salidas CX-II con o sin ruedas de consolidación.

- Rentable.

- Alto rendimiento - velocidades de siembra más rápidas, gran capacidad de tolva.

Características

Características

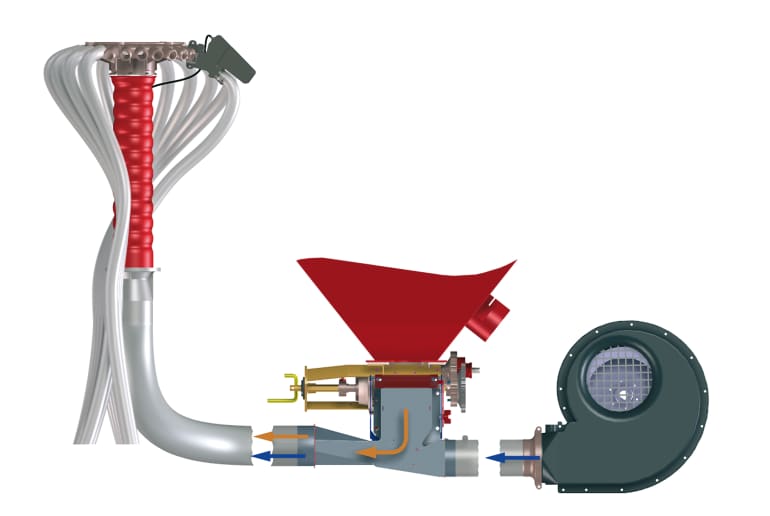

- El sistema de distribución neumático Accord es el más fabricado, vendido y usado en el mundo. Ha demostrado su fiabilidad a lo largo de los años y consigue la distribución uniforme de la dosis de semilla en todo el ancho de la barra de siembra.

- El aire y la semilla se convierten en un fluido turbulento que se reparte uniformemente en el cabezal distribuidor

- El cabezal distribuidor normalmente se sitúa en un lugar protegido en el interior de la tolva.

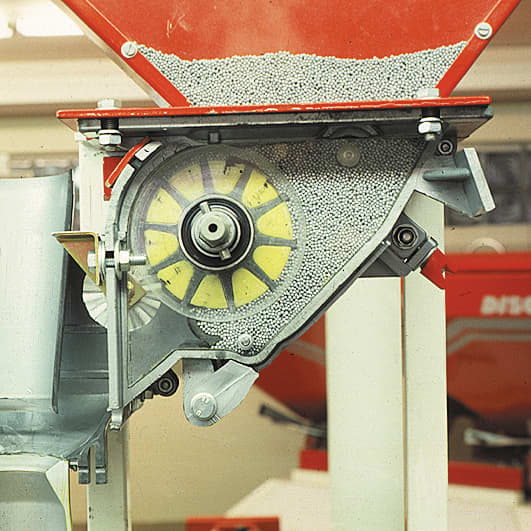

- El sistema dosificador central proporciona la cantidad adecuada y precisa de semillas entre el rango de 1,8 y 380kg/ha

- Al sembrar semillas de tamaño muy pequeño es necesario activar el engranaje rojo y limitar el volumen disponible en el dosificador. todo ello se hace sin usar herramientas ni montar o desmontar elementos adicionales

- El dosificador (versiones mecánicas) recibe el movimiento directamente de la rueda al suelo. Los dosificadores eléctricos pueden conectarse a una señal de radar o GPS (suficientemente fiable) o incluso a una señal de sensor instalado en la rueda de la máquina

- El dosificador se situa en el centro debajo de la tolva o en una posición muy ventajosa para que el usuario pueda realizar pruebas de calibración comodamente.

Características técnicas

Características técnicas

Descargar catálogo| Modelo | Kverneland Satio 1030 | Kverneland Satio 1040 | |

|---|---|---|---|

| Chasis | Suspendido | Suspendido | |

| Ancho de trabajo (m) | 3 | 4 | |

| Ancho de circulación (m) | 3 | 4 | |

| Capacidad de Tolva (litros) | 750 | 750 | |

| Extensión de Tolva (litros) | 250 | 250 | |

| Tolva de vaciado rápido | Básico | Básico | |

| Sensor de nivel de tolva | Básico | Básico | |

| Enganche 3r punto | Cat.II / Cat.III | Cat.II / Cat.III | |

| Enganche brazos inferiores | Cat.II / Cat.III-N / Cat.III | Cat.II / Cat.III-N / Cat.III | |

| Tipo de rueda | 26x12,00 | 26x12,00 | |

| Turbina a 1.000 rpm | Variante | Variante | |

| Turbina a 540 rpm | Variante | Variante | |

| Turbina tracción hidráulica | Básico | Básico | |

| Dosificador Tracción Cadena | Básico | Básico | |

| Nº de dosificadores Clásicos (NO ELDOS) | Básico (1) | Básico (1) | |

| Microdosificación | Básico | Básico | |

| FGS (Tram-Lines) | Variante | Variante | |

| Signus (Tram-Lines) | Variante | Variante | |

| Ajuste de la dosis de siembra | Variante | Variante | |

| Dosificación (mín-máx) - Kg/ha | 2 - 380kg/ha | 2 - 380kg/ha | |

| Válvulas de cierre (Tram-Lines) | Variante | Variante | |

| Cierre manual de 1/2 máq. | Variante | Variante | |

| Marcador de pre-nacencia | Variante | Variante | |

| Nº de salidas a 12,5cm | Básico (24) | Básico (32) | |

| Nº de salidas a 25,0cm | Básico (12) | Básico (16) | |

| Discos CX-II con rueda de consolidación *1 | Básico | Básico | |

| Discos CX-II SIN rueda de consolidación *1 | Variante | Variante | |

| Disco CX-II, Ø (mm) | 325 | 325 | |

| Ruedas de consolidación Ø (mm) | 250 x 42 | 250 x 42 | |

| Presión del disco CX-II (kg) | 5 - 50 | 5 - 50 | |

| Ajuste manual presión siembra (tensor) | Básico | Básico | |

| Rastrilla trasera de dedos "S" (10 mm) | Variante | Variante | |

| Borra-huellas | Básico | Básico | |

| Kit calibración | Básico | Básico | |

| Caja de herramientas y juego de calibración | Variante | Variante | |

| Trazadores pleg. con disco dentado | Variante | Variante | |

| Escalón de carga / Plataforma | Básico | Básico | |

| Luces de carretera | Variante | Variante | |

| Caudal hidráulico Turbina hid.: 4.400rpm (l/min) | 30 | 30 | |

| Potencia mínima necesaria (cv) | 73 | 98 | |

| Peso (kg) con salidas | 780 - 1.260 | 880 - 1.450 |

*1: Los discos CX-II de este modelo pueden solicitarse con y sin rueda de consolidación por configuración, pero no se pueden transformar en la versión alternativa a posteriori, pues el propio disco es distinto.

Características técnicas

Características técnicas

Descargar catálogoModel |

Satio 1030 |

Satio 1040 |

Frame |

mounted |

mounted |

Working/transport width (m) |

3.0 |

4.0 |

Hopper capacity (l) |

750 |

750 |

Hopper extensions - option (l) |

250 |

250 |

Mechanic metering device (N°) |

Standard (1) |

Standard (1) |

Micro metering |

Standard |

Standard |

Seed quantity (min. - max.) |

2 - 380kg/ha |

2 - 380kg/ha |

No. of coulters at 12.5cm distance (N°) |

24 |

32 |

No. of coulters at 25.0cm distance (N°) |

12 |

16 |

Min. power requirement (HP/kW) |

73/54 |

98/72 |

Weight (kg) with coulters |

780 - 1260 |

880 - 1450 |

*1: Los discos CX-II de este modelo pueden solicitarse con y sin rueda de consolidación por configuración, pero no se pueden transformar en la versión alternativa a posteriori, pues el propio disco es distinto.