Kverneland 7740

Encintadoras | Encintadoras de mesa

Encintadora de perfil bajo que garantiza una carga y descarga suave de las pacas

Encintadora de rotación de mesa arrastrada para trabajos pesados que manipula pacas redondas de hasta 1200 kg

Destacado

- Trailed turntable wrapper with self-loading mechanism

- Able to handle bales up to 1200kg

- Gentle loading & unloading of the bales

- Able to wrap and carry a second bale on the loading arm

- Optional DuoWrap feature for faster wrapping

Descripción

La encintadora arrastrada Kverneland 7740 es ideal para agricultores que encintan un gran número de pacas. La posibilidad de encintar una paca y recoger otra durante el encintado permite un mayor rendimiento. La mesa de perfil bajo permite un funcionamiento estable incluso en condiciones accidentadas o en laderas y también proporciona una descarga suave de la paca encintada. La Kverneland 7740 ofrece un diseño robusto y es capaz de manejar pacas de hasta 1200 kg. Se peude configurar con pretensor doble DuoWrap o High Speed Pack (HSP).

Destacado

- Encintadora de rotación de mesa arrastrada con chasis robusto que puede encintar pacas de hasta 1200 kg.

- El diseño de perfil bajo ofrece una carga y descarga suave de las pacas junto con una muy buena estabilidad.

- Capaz de transportar una paca adicional en el brazo de carga durante el encintado.

- Configurable con pretensor doble DuoWrap o High Speed Pack (HSP) para un encintado más rápido.

- La versión de control por ordenador ofrece un funcionamiento totalmente automático.

Características

Características

- El volteador de pacas garantiza que las pacas se descarguen por la cara plana, lo que ofrece una mayor protección contra los daños.

- El paquete de alta velocidad (HSP) garantiza una velocidad de encintado óptima y elevada, gracias al sensor Optispeed y al doble preestiramiento DuoWrap.

- Control por leva (M): Control sencillo con parada automática del extremo de enrollado

- Control por ordenador (C): Funcionamiento totalmente automático o semiautomático

- Accionamiento hidráulico para un corte y sujeción precisos.

- Corta y sujeta el plástico de forma eficiente para el siguiente ciclo.

- Preestirador de doble film DuoWrap para un encintado más rápido.

- El estiramiento uniforme del film reduce el riesgo de desgarro.

- Sistema de carga del rollo muy fácil.

- Encintado estable y descarga suave.

- Baja altura de carga/descarga.

- Reduce el riesgo de daños.

- Los brazos de carga garantizan un transporte suave, seguro y eficaz de las pacas, incluso sobre la marcha.

- La mesa giratoria tiene dos rodillos motrices diseñados para una gran estabilidad de la paca y una rotación suave y uniforme. El brazo de carga ajustable permite recoger y cargar la paca sobre la marcha.

- El diseño de la mesa baja permite una alta velocidad de rotación.

The DuoWrap sees twin film dispensers integrated into the Kverneland 7710, 7730 and 7740 mounted and trailed turntable wrappers. DuoWrap gives up to 50% faster wrapping compared to single film models, whilst also reducing the risk of film breaking during wrapping. Utilising a 66% overlap of the two films as they are applied to the bale, DuoWrap ensures even coverage without excessive wrinkling of the film.

The HSP is a combination of two developments. The first, DuoWrap allows wrapping with two film overlap of 66% , the time to cover the bale is reduced by one third. The second development, named OptiSpeed, is electronic control of the wrapper table rotation speed.

The OptiSpeed optimizes the rotation speed of the table to allow the fastest wrapping possible in all conditions without being limited to fixed values.

HSP option is available on the 7710C fully mounted model and 7740C heavy duty trailed models.

- Two large diameter rollers, both of which are driven, ensure bale rotation even in the most difficult conditions.

- Four endless belts carry and rotate the bale evenly during wrapping with no risk of film damage.

- The two large diameter conical side support rollers ensure that the bale is kept in a central position on the rotating table during wrapping operation.

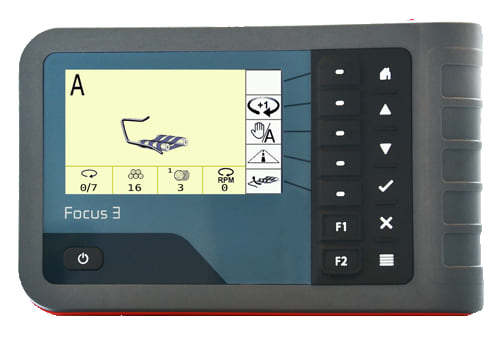

Computer Control (C)

- The computer (Focus 3) controlled C models turn the wrapper into a fully automatic machine offering either a fully automatic operation or a choice of manual override or function by function operation.

- Choose for example that you want the bale to wrap automatically off. One operator does the entire process of loading, wrapping and stacking when loaded, but remain on the wrapping table until you confirm that you want to offload.

- Compact joystick allows temporary manual control of the bale loading and turntable rotation/tip.

Remote Control (R)

- An advanced remote controlled version is available as an option on C versions of turntable wrappers. Place the bale on the wrapper, press one key on the remote control, and the wrapping process starts.

- The previously wrapped bale is stacked and the next one picked up while the machine continues wrapping.

- Press another key when wrapping is completed and the bale is tipped off. One operator does the entire process of loading, wrapping and stacking.

Mechanical Cable Control (M)

- The manual versions (M) are controlled with manual cable control with levers.

- A wrap and bale counter is fitted for easier control of film layers, as well as number of bales wrapped.

- An automatic table stop that is controlled by the wrap-and-bale counter is fitted as standard.

- This converts the wrapper from manual to semi-automatic, as it allows the wrapping function to stop automatically at the set number of table revolutions.

- The Kverneland 7730 and7740 are designed with a low table height and wheels located at the very rear of the machine.

- The position of rear wheels ensures a low table height provide low loading and unloading height.

- The low slung chassis combined with a short lifting height, provides fast transfer of the bale from arm to turntable.

- 1) The low mounted table design allows higher rotation speed an.

- 2) The short lifting height provides fast transfer of bale from arm to turntable.

- 3) It ensures vast and gentle on-the-move unloading with no need for a fall damper.

- On the Kverneland 7710, 7730 and 7740 a hydraulically operated film cutter cuts and holds the film in position ready to wrap the next bale.

- An easy to use solution without the need to manually control the operation.

Características técnicas

Características técnicas

Descargar catálogo| 7740 M | 7740 C | ||

|---|---|---|---|

| Tamaño máx. paca (m) | 1.20 x 1.50 | 1.20 x 1.50 | |

| Peso máx. paca (kg) | 1200 | 1200 | |

| Control | Levas | Ordenador |

Características técnicas

Características técnicas

Descargar catálogoMax Bale Size |

Max Bale Weight |

Control System |

|

7740 M |

1.20x1.50m |

1200kg |

Cable Control (M) |

7740 C |

1.20x1.50m |

1200kg |

Computer Control (C) |