Kverneland 4300

Segadoras | Segadoras Acondicionadoras

Con una gran variedad de modelos, las posibilidades son infinitas.

Segadora acondicionadora arrastrada con multitud de aplicaciones.

Destacado

- SuperFloat dual action suspension

- Optional BX belt for maximum flexibility

- FlipOver wide spreading kit

- Optional hydraulic stubble height adjustment

- Round discs - less susceptible to stone impact

Descripción

Las segadoras acondicionadoras arrastradas Kverneland 4300 están disponibles en anchuras de trabajo de 2,81 a 3.57 m y sus especificaciones incluyen lanza lateral o central y la opción de acondicionador SemiSwing o de rodillos. Con características como la barra de corte de bajo mantenimiento, la suspensión SuperFloat y opcionales como la cinta BX y el esparcidor FlipOver, esta segadora está preparada para satisfacer cualquier demanda con un rendimiento excepcional. El cambio de hilerado simple a cinta hileradora o a esparcido ancho es muy fácil y se realiza en poco tiempo.

Características

Características

- Kverneland uses round discs. Round discs are less susceptible to stone impact, and reduce shock loads in the transmission.

- Stones are expelled immediately, before they have any chance of becoming jammed. The benefits are lower repair and maintenance costs - at the same time as a clean and aggressive cut.

- The cutterbar has a high oil capacity, ensuring a very low working temperature. This ensures an efficient oil cooling and lubrication of the entire cutterbar.

- The long curved gear wheels running in oil provides a very quiet and reliable power transmission.

- The fully welded cutterbar gives a very stiff and strong design for high durability.

- With the ProFit quick knife change system, maintenance of the cutting ability is easy. The knives are changed by one simple operation using the special lever.

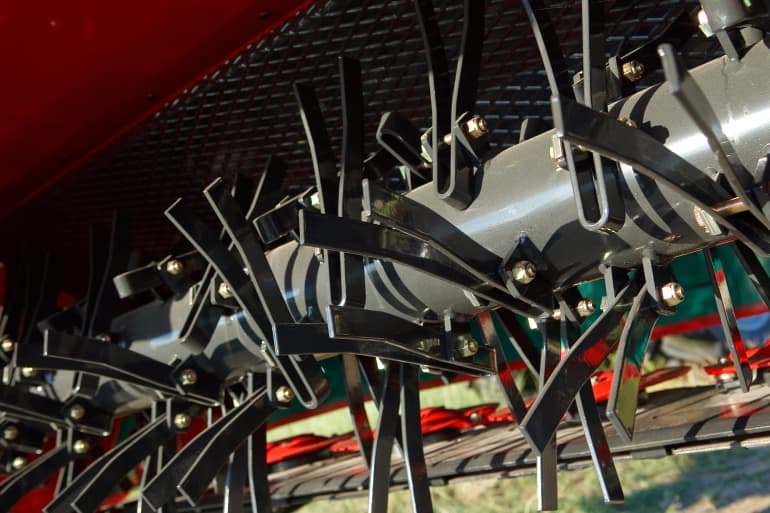

- The SemiSwing conditioner system combines the aggressive conditioning seen from fixed fingers with the excellent tine protection typically associated with free swinging tines.

- During normal operation the tines are fixed for effective conditioning, but if a SemiSwing tine comes into contact with an obstacle, force will exceed 22kg (48.5lbs) and it will spring back and leave a generous space for the obstacles up to 103mm to pass.

- The complete conditioner tine has been redesigned to move the centre of gravity. The result is that the tine will stay in position when hitting the crop, to give full conditioner effect and to minimise wear and tear on the turning points.

- The angle and position of the SemiSwing tines give a better crop transport. The crop is moved away from the conditioner rotor, resulting in reduced risk of blockages and full effect of the conditioner plate.

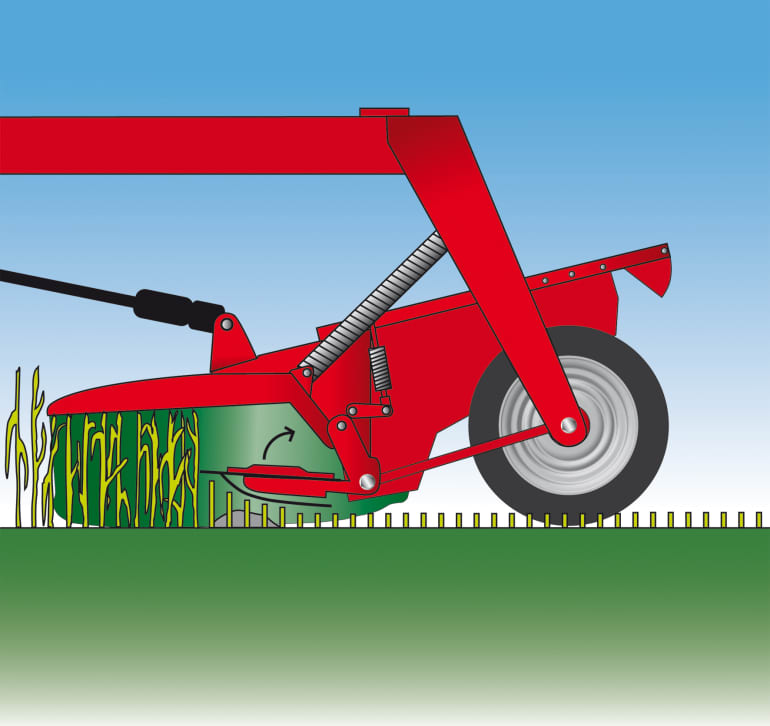

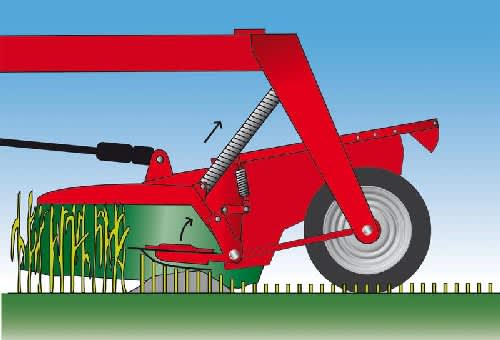

- The Kverneland 4300 series benefits from the patented Kverneland ‘SuperFloat’ flotation suspension system.

- The cutterbar and the conditioner unit are suspended independently from the main chassis via two long adjustable springs, allowing ground contours to be closely followed. In addition the cutterbar also benefits from its own separate suspension mechanism, ensuring an even cutting height

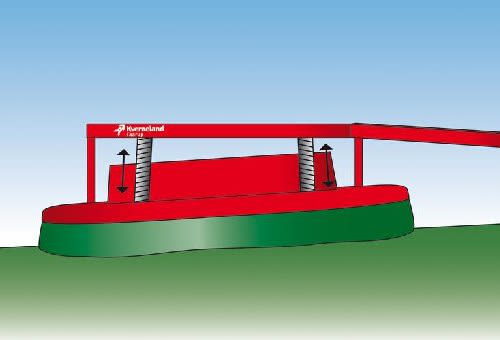

- The Kverneland 4300 series can be fitted with the versatile Kverneland BX Auto-Swather belt to place two swaths into one.

- In this way the large swaths for large foragers or balers can be prepared, to speed up the collection of the crop.

- The swath belt can be raised and lowered from the tractor seat during operation. This allows you to adapt to each individual situation and requirement, without wasting valuable time.

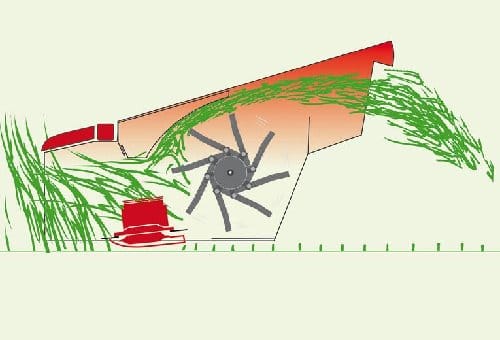

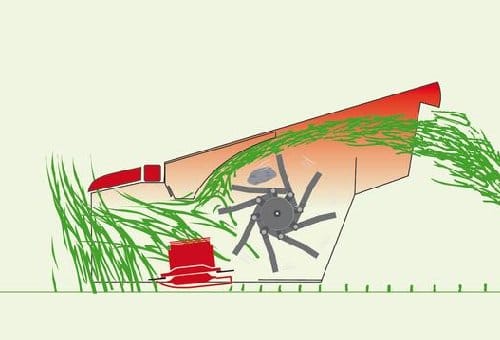

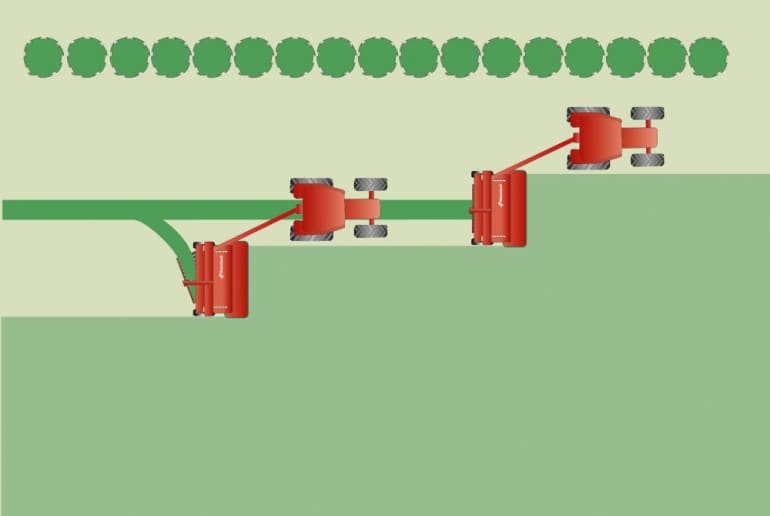

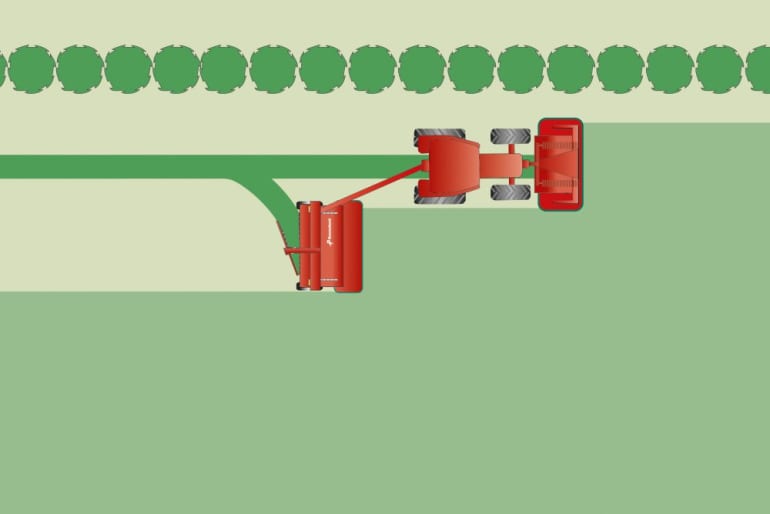

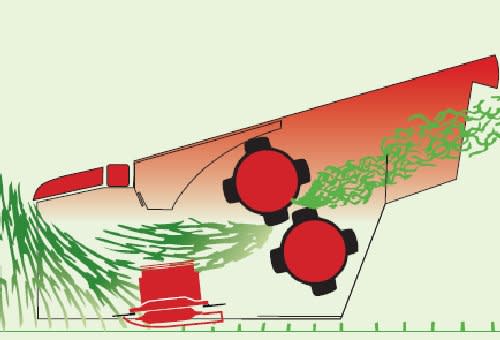

- As an option the Kverneland mower conditioners can be equipped with widespreading equipment. In this way, crop can be cut and spread in one operation, saving both time and at least one tedder operation.

- The spreading vanes of the Kverneland FlipOver system are placed further back on the mowing unit than with conventional systems.

- This is thanks to the spreading plate positioned far to the rear when in use. The improved distance between the conditioning rotor and the spreading vanes gives a more even spreading across the entire working width. A more even spreading ensures a better wilting.

- The Kverneland roller versions are equipped with full width chevron rollers, quickly taking the cut crop off of the cutting discs and providing gentle and effective conditioning of fragile crops like lucerne/alfalfa, reducing leaf loss to a minimum.

- The design of the rollers ensures, that the crop is placed in an even, fluffy swath.

- The conditioning intensity is varied without use of tools, by adjusting the roller pressure exerted between top and bottom roller.

- The SemiSwing conditioner system combines the aggressive conditioning seen from fixed fingers with the excellent tine protection typically associated with free swinging tines.

- During normal operation the tines are fixed for effective conditioning, but if a SemiSwing tine comes into contact with an obstacle, force will exceed 22kg (48.5lbs) and it will spring back and leave a generous space for the obstacles up to 103mm to pass.

- The complete conditioner tine has been redesigned to move the centre of gravity. The result is that the tine will stay in position when hitting the crop, to give full conditioner effect and to minimise wear and tear on the turning points.

- The angle and position of the SemiSwing tines give a better crop transport. The crop is moved away from the conditioner rotor, resulting in reduced risk of blockages and full effect of the conditioner plate.

- The Kverneland 4300 series benefits from the patented Kverneland ‘SuperFloat’ flotation suspension system.

- The cutterbar and the conditioner unit are suspended independently from the main chassis via two long adjustable springs, allowing ground contours to be closely followed. In addition the cutterbar also benefits from its own separate suspension mechanism, ensuring an even cutting height

- The Kverneland 4300 series can be fitted with the versatile Kverneland BX Auto-Swather belt to place two swaths into one.

- In this way the large swaths for large foragers or balers can be prepared, to speed up the collection of the crop.

- The swath belt can be raised and lowered from the tractor seat during operation. This allows you to adapt to each individual situation and requirement, without wasting valuable time.

- As an option the Kverneland mower conditioners can be equipped with widespreading equipment. In this way, crop can be cut and spread in one operation, saving both time and at least one tedder operation.

- The spreading vanes of the Kverneland FlipOver system are placed further back on the mowing unit than with conventional systems.

- This is thanks to the spreading plate positioned far to the rear when in use. The improved distance between the conditioning rotor and the spreading vanes gives a more even spreading across the entire working width. A more even spreading ensures a better wilting.

- The Kverneland roller versions are equipped with full width chevron rollers, quickly taking the cut crop off of the cutting discs and providing gentle and effective conditioning of fragile crops like lucerne/alfalfa, reducing leaf loss to a minimum.

- The design of the rollers ensures, that the crop is placed in an even, fluffy swath.

- The conditioning intensity is varied without use of tools, by adjusting the roller pressure exerted between top and bottom roller.

- Kverneland uses round discs. Round discs are less susceptible to stone impact, and reduce shock loads in the transmission.

- Stones are expelled immediately, before they have any chance of becoming jammed. The benefits are lower repair and maintenance costs - at the same time as a clean and aggressive cut.

- The cutterbar has a high oil capacity, ensuring a very low working temperature. This ensures an efficient oil cooling and lubrication of the entire cutterbar.

- The long curved gear wheels running in oil provides a very quiet and reliable power transmission.

- The fully welded cutterbar gives a very stiff and strong design for high durability.

- With the ProFit quick knife change system, maintenance of the cutting ability is easy. The knives are changed by one simple operation using the special lever.

- The SemiSwing conditioner system combines the aggressive conditioning seen from fixed fingers with the excellent tine protection typically associated with free swinging tines.

- During normal operation the tines are fixed for effective conditioning, but if a SemiSwing tine comes into contact with an obstacle, force will exceed 22kg (48.5lbs) and it will spring back and leave a generous space for the obstacles up to 103mm to pass.

- The complete conditioner tine has been redesigned to move the centre of gravity. The result is that the tine will stay in position when hitting the crop, to give full conditioner effect and to minimise wear and tear on the turning points.

- The angle and position of the SemiSwing tines give a better crop transport. The crop is moved away from the conditioner rotor, resulting in reduced risk of blockages and full effect of the conditioner plate.

- The Kverneland 4300 series benefits from the patented Kverneland ‘SuperFloat’ flotation suspension system.

- The cutterbar and the conditioner unit are suspended independently from the main chassis via two long adjustable springs, allowing ground contours to be closely followed. In addition the cutterbar also benefits from its own separate suspension mechanism, ensuring an even cutting height

- The Kverneland 4300 series can be fitted with the versatile Kverneland BX Auto-Swather belt to place two swaths into one.

- In this way the large swaths for large foragers or balers can be prepared, to speed up the collection of the crop.

- The swath belt can be raised and lowered from the tractor seat during operation. This allows you to adapt to each individual situation and requirement, without wasting valuable time.

- As an option the Kverneland mower conditioners can be equipped with widespreading equipment. In this way, crop can be cut and spread in one operation, saving both time and at least one tedder operation.

- The spreading vanes of the Kverneland FlipOver system are placed further back on the mowing unit than with conventional systems.

- This is thanks to the spreading plate positioned far to the rear when in use. The improved distance between the conditioning rotor and the spreading vanes gives a more even spreading across the entire working width. A more even spreading ensures a better wilting.

- The Kverneland roller versions are equipped with full width chevron rollers, quickly taking the cut crop off of the cutting discs and providing gentle and effective conditioning of fragile crops like lucerne/alfalfa, reducing leaf loss to a minimum.

- The design of the rollers ensures, that the crop is placed in an even, fluffy swath.

- The conditioning intensity is varied without use of tools, by adjusting the roller pressure exerted between top and bottom roller.

Características técnicas

Características técnicas

Descargar catálogo| Modelo | 4328 LT | 4332 LT | 4332 CT | 4332 LR | 4332 CR | 4336 LT | 4336 LR | 4336 CT | |

|---|---|---|---|---|---|---|---|---|---|

| Lanza | Lateral | Lateral | Central | Lateral | Central | Lateral | Lateral | Central | |

| Acondicionador | SemiSwing | SemiSwing | SemiSwing | Rodillos | Rodillos | SemiSwing | Rodillos | SemiSwing | |

| Ancho de trabajo (m) | 2.81 | 3.16 | 3.16 | 3.16 | 3.16 | 3.57 | 3.57 | 3.57 | |

| Ancho de circulación (m) | 2.70 | 3.00 | 3.00 | 3.00 | 3.00 | 3.40 | 3.40 | 3.40 | |

| TDF (rpm) | 540/1000 | 540/1000 | 540/1000 | 540/1000 | 540/1000 | 540/1000 | 540/1000 | 540/1000 | |

| Potencia mín. necesaria (cv) | 70 | 80 | 80 | 80 | 80 | 90 | 90 | 90 | |

| Número de discos/cuchillas | 7/14 | 8/16 | 8/16 | 8/16 | 8/16 | 9/18 | 9/18 | 9/18 |

Características técnicas

Características técnicas

Descargar catálogoWorking Width |

No of Discs |

Conditioner |

Power Requirements |

|

4324 LR |

2.40m |

6 |

Roller Conditioning |

44/60 kW/hp |

4328 LT |

2.81m |

7 |

SemiSwing Steel Tines |

50/70 kW/hp |

4332 LT |

3.16m |

8 |

SemiSwing Steel Tines |

60/80 kW/hp |

4332 LR |

3.16m |

8 |

Roller Conditioning |

60/80 kW/hp |

4336 LT |

3.57m |

9 |

SemiSwing Steel Tines |

66/90 kW/hp |

4336 LR |

3.57m |

9 |

Roller Conditioning |

66/90 kW/hp |