Kverneland 5387 MT/MT BX/MR - 5395 MT/MT BX

Segadora acondicionadora tipo mariposa versátil con una extraordinaria capacidad de ajuste

Descripción

Siega de alto rendimiento

Los modelos 5387 y 5395 se han desarrollado a partir del bastidor de la serie 5300 e incluyen características ya consolidadas como la suspensión QuattroLink, el acondicionador de mayales de acero SemiSwing con doble ajuste de la chapa acondicionadora y el acondicionador de rodillos. Estos modelos se han desarrollado para obtener la máxima productividad y ofrecen un excelente seguimiento del terreno, un manejo sencillo y una versatilidad excepcional.

Compuesta por dos unidades de siega de 3,2 m y 8 discos redondos (5387) ó 3,6 m y 9 discos redondos (5395, esta combinación funciona en tractores a partir de 180 CV. Son fáciles de manejar y funcionan de serie con un mando de preselección para la elevación/descenso (individual) de las unidades de siega, las cintas de hilerado y el ajuste de la presión sobre el suelo.

Tanto la 5387 MT como la 5395 MT están disponibles en versiones BX con cintas de hilerado para una recogida eficaz del forraje. Las cintas ofrecen importantes posibilidades para mejorar la productividad y la calidad de la producción. Las cintas hileradoras están diseñadas para trabajar con grandes volúmenes de forraje. Con correas de alta velocidad que funcionan hasta a 1.500 rpm, pueden transportar grandes volúmenes de forraje y colocar la hierba en hileras estrechas y uniformes. El sistema hidráulico de centro abierto del tractor y la caja de control de preselección, que viene de serie con la máquina, accionan los modelos Kverneland 5387 MT y 5395 MT BX.

Características:

- Suspensión QuattroLink para una excelente capacidad de seguimiento del terreno.

- Doble ajuste de la chapa acondicionadora en los modelos SemiSwing, tanto en la parte delantera como trasera, para adaptarse a condiciones específicas.

- Versiones BX disponibles para hilerar, opcionalmente desmontables.

- Protección BreakAway en toda la anchura de trabajo.

- Rango de movimiento de 700 mm en vertical y 30º en transversal.

- Excelente distribución del peso durante el transporte. Pies de estacionamiento integrados.

Los modelos 5387 y 5395 se basan en la plataforma de la serie 5300 e incluyen características bien establecidas como el concepto de suspensión QuattroLink, el acondicionamiento SemiSwing con púas de acero o rodillos de goma y el doble ajuste de la placa acondicionadora. Estos modelos se han desarrollado para obtener la máxima productividad y ofrecen un excelente seguimiento del terreno, un manejo sencillo y una versatilidad excepcional.

Características

Racecar Technology Applied for Mower Conditioners

What makes the QuattroLink suspension unique? The mowing unit is pulled by four suspension arms fitted onto a fixed carrying arm that allows the mowing unit to float independently over the field, adjusting highly accurately and instantly to any changes in ground contours.

No Compromises on Flexibility

The mowing pattern is extremely flexible with a vertical working range of 700mm up and down and a transverse working range of 30°. The 4 arm suspension concept ensures constant ground pressure during working operations.

How You Will Benefit from QuattroLink

Like a race car you want better tracking, ability to go at faster speed and adjust instantly to changing field conditions when operating your mower conditioner. These are the main benefits you will experience when running the kverneland 3300 series and 53100 MT Vario. The four suspension arms provide the mowing unit with an exceptional flexibility in adapting instantly to demanding ground contours inviting for higher speed and more productivity.

Our NonStop BreakBack system just got even better. With the new QuattroLink suspension this system now offers protection across the full working width of the mower, including the part closest to the tractor. There are no limiting factors on the inside part of the mower, giving the driver true peace of mind. When hitting an obstacle in the field, the mowing unit will instantly move backwards and up, and then return to the original position.

Generous ground clearance is secured across the complete cutterbar, including the inside area. When lifting the mower on headlands, the mowing unit is raised and the carrying arm is tilted to a 10° angle. This provides a ground clearance of minimum 500mm across the full working width. When lowering the carrying arm is lowered evenly, with the complete mowing unit touching down at the same time across the full width, avoiding unnecessary stress and wear on the mower.

Compact During Transport

The mower in an above 90o position for stable transport. Transport height below 4.0m - transport width below 3.0m. Optionally the outer FlexProtect guards fold into transport position, so there is no need of leaving the tractor seat.

Parking, Safe and Sure-Footed

With the integrated parking device, storage is made easy and convenient, requiring a minimum of space during winter storage. The mower is firmly parked on a strong and stable parking foot.

Conditioning tailored to varying conditions

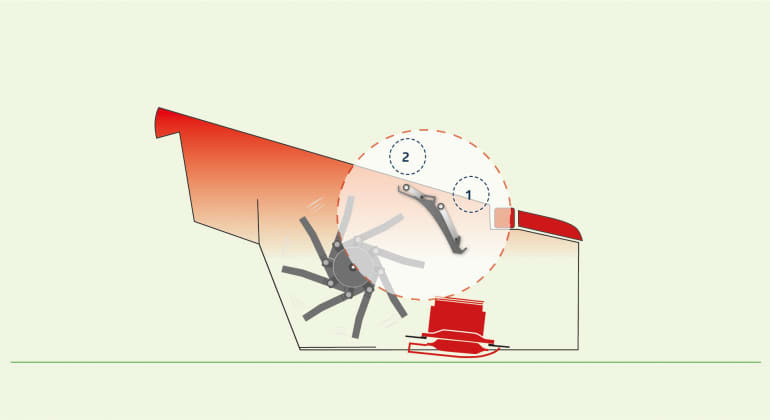

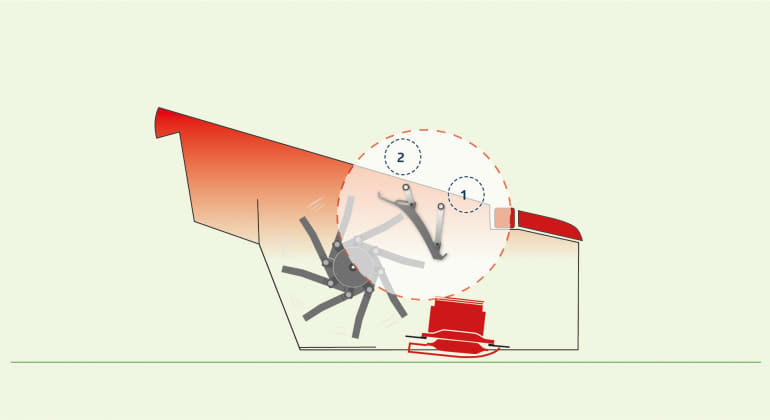

The conditioner plate can be adjusted at both front and rear ends to customize the conditioner to crop intensity. Use the two handles to set the desired conditioning intensity.

The front (1) is adapting to crop height. Low position for low crop, high position for high crop. The rear (2) is adjusted for perfect crop flow into either swath or full widespreading.

BX belt solution for added versatility

The BX version offers even more options, when it comes to adapting to changing circumstances. When in use it allows narrow swathing and is optionally dismountable for less total weight.

Swath Plates Automatically Expand

Swath plates automatically expand when being slid inwards to support efficient and accurate swathing. When widespreading the plates are moved to the outside - no need for dismantling.

Widespreading options

Two accessory kits are optionally available for widespreading.

- Spreading vanes mounted on rear plate

- FlipOver widespreading kit for 100% spreading and quick change over.

- Kverneland uses round discs. Round discs are less susceptible to stone impact, and reduce shock loads in the transmission.

- Stones are expelled immediately, before they have any chance of becoming jammed. The benefits are lower repair and maintenance costs - at the same time as a clean and aggressive cut.

- The cutterbar has a high oil capacity, ensuring a very low working temperature. This ensures an efficient oil cooling and lubrication of the entire cutterbar.

- The long curved gear wheels running in oil provides a very quiet and reliable power transmission.

- The fully welded cutterbar gives a very stiff and strong design for high durability.

- With the ProFit quick knife change system, maintenance of the cutting ability is easy. The knives are changed by one simple operation using the special lever.

Características técnicas

Características técnicas

Descargar catálogo

|

Ancho de trabajo |

Núm. de discos |

Acondicionador |

Potencia requerida |

5387 MT |

8,75 m |

2x8 discos redondos |

Mayales SemiSwing |

180 cv |

5387 MT |

8,75 m |

2x8 discos redondos |

Rodillos |

180 cv |

5387 MT BX |

8,75 m |

2x8 discos redondos |

210 cv |

|

5395 MT |

9,50 m |

2x9 discos redondos |

Mayales SemiSwing |

210 cv |

5395 MT BX |

9,50 m |

2x9 discos redondos |

Mayales SemiSwing |

240 cv |